Cleanrooms are designed & constructed specifically to have environmentally controlled & enclosed areas, wherein, the concentration of airborne dust (particulate contaminants) & gases (molecular contaminants) are to be maintained within the desired limits as per the process requirements.

Generally, industrial cleanrooms are used in the manufacturing of electronic hardware such as integrated circuits (ICs), hard drives etc., & In biotechnology and medicine, cleanrooms are designed, where there is a necessity to have areas free of bacteria, viruses, or other pathogenic substances.

The Problem

Extreme Cleanliness is the necessity while manufacturing Semiconductors, hard disks etc., since even a few particles at Micro levels and chemical contaminants at Nano levels may cause a major failure and subsequent losses to the manufacturer by affecting their production yield and product let-downs. Cleanliness of the design of cleanrooms are quantified by standards such as ISO 14644, US Federal Standard 209E and others. To achieve them according to the design requirements as per the regulations & standards, the particulate and chemical filters must be properly selected, installed & maintained throughout the usage of controlled ambient of those cleanrooms. The impact to environment and its resultant damages in case of some emergencies, due to the products used in the design of cleanrooms are governed by standards such as FM, UL & others.

The Solution

We intend to explain some of those chemicals and would like to propose our solutions for removing them in the exhaust or prior to re-circulation in the air handlers catering SPA & SALON areas in this submittal.

JAF have more than 6 decades of experience and through its extensive involvement in the industry, can offer best recommendations for both particulate and molecular control in the field of microelectronics and semiconductor contamination control. JAF products undergo extensive quality compliance while manufacturing for this industry to meet the various international standards, such as, FM, UL, ISO 9000, ISO 13485 and others.

AIR FILTERATION

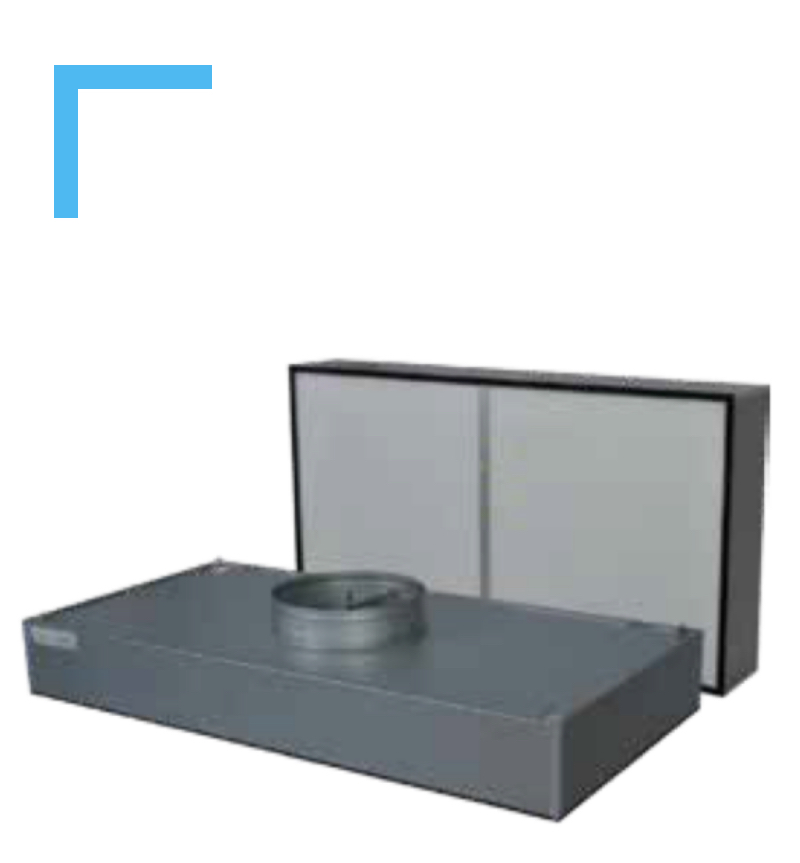

LunaCel HC

- H10, H13, H14, U15

- Ultra-fine fire retardant fibreglass

- Corrugated aluminium

- Galvanized steel, Stainless steel

- Standard depth 149mm & 292mm

- UL certified

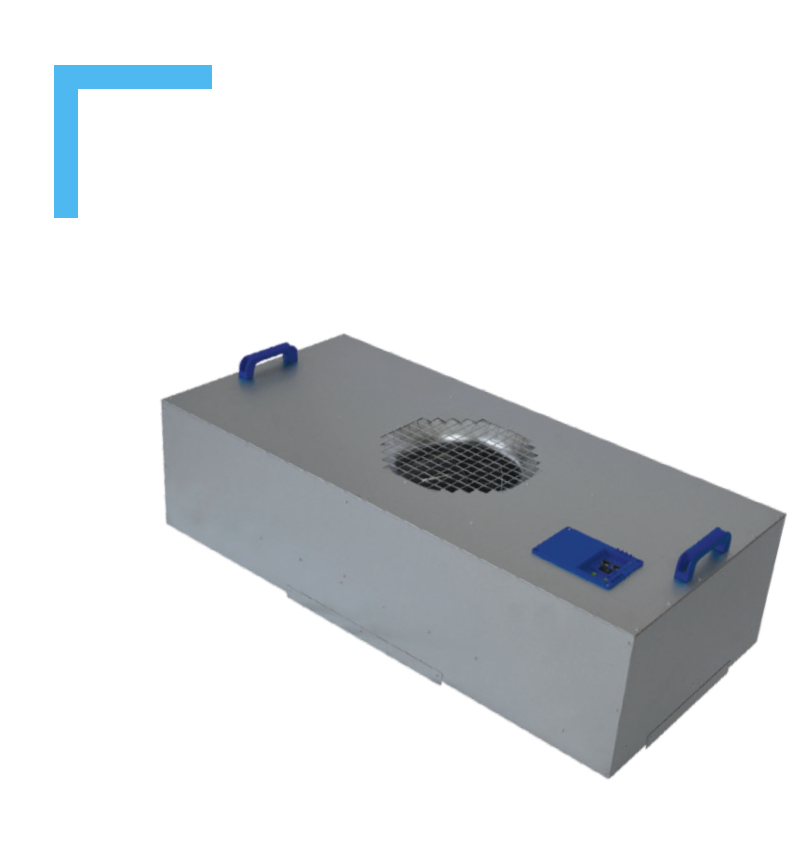

LunaKleen Hood

- H13, H14, U15

- Ultra-fine fibreglass

- Anodized aluminium, Stainless steel

- Collar size 10” , 12” and 14”

- Standard depth 152mm

- Disposable unit for optimum

- filter performance with an individual ducted system

- UL certified

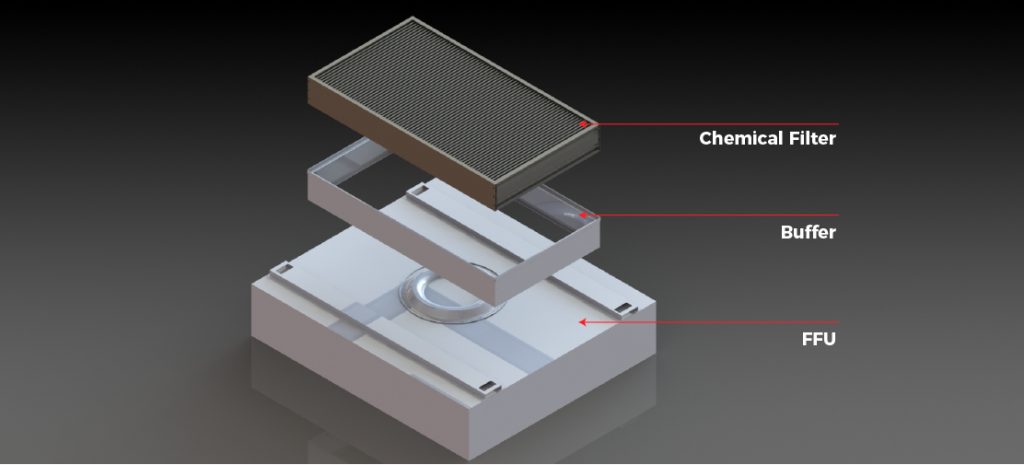

LunaFan AC/EC

- LunaKleen as filter for Fan Filter Unit

- Moisture resistant, fire retardant fibreglass

- Aluminium, Stainless steel, Galvalume

- Standard module 2’x2’, 2’x4’ and 4’x4’

- UL certified

- Available in single phase (1p) and three phase (3p)

- With variable speed controller or Smart Electronic Control (EC) FFU System

AIR QUALITY IDENTIFICATION STEP 1: IDENTIFY

Reactivity Measurement Kit

- Measure Air Reactivity as per ANSI/ISA-71.04.2013

- Qualifies & Quantifies the presence of Reactive Gases in the controlled Environment

- Handy tool & Very Reliable method to provide Air Quality Assessment Reports

- Can measure performance of the Chemical Filters installed

- Utilizes constant-current coulometricmethod accordance to ASTM B 825-02 to determine the corrosion rate of the exposed environment

STEP 2: ELIMINATE

Molecular Filtration

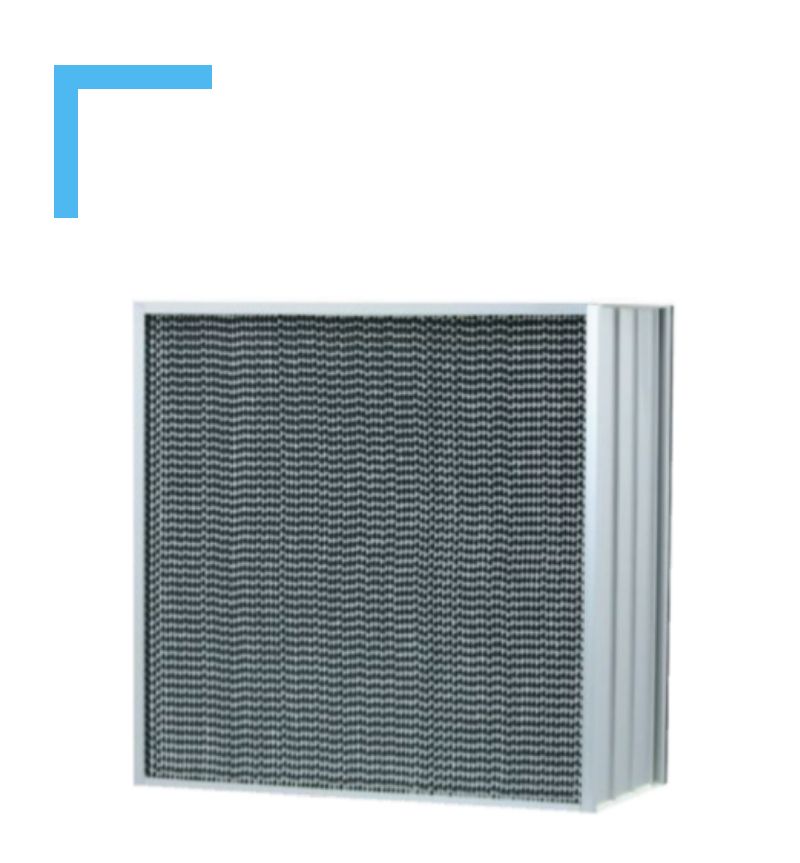

TetraCarb CE

- Mini-Pleated, Compact & Rigid Construction with various choices of special Chemical Media

- Customized Media Selection for every requirement

- Activated Carbon Bead, Ion Exchange Resin

- Available as Standard 2” fi lter thickness in Aluminium Frames

- Other non-standard sizes & frame materials also available

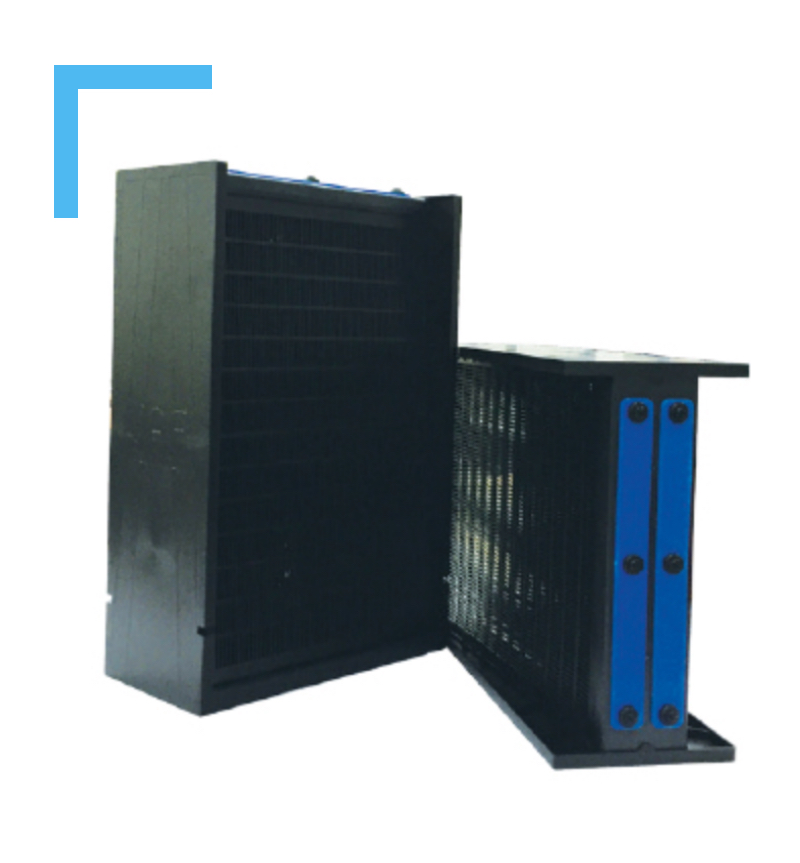

TetraCarb TY

- Exchangeable type Trays with various choices of special Chemical Media

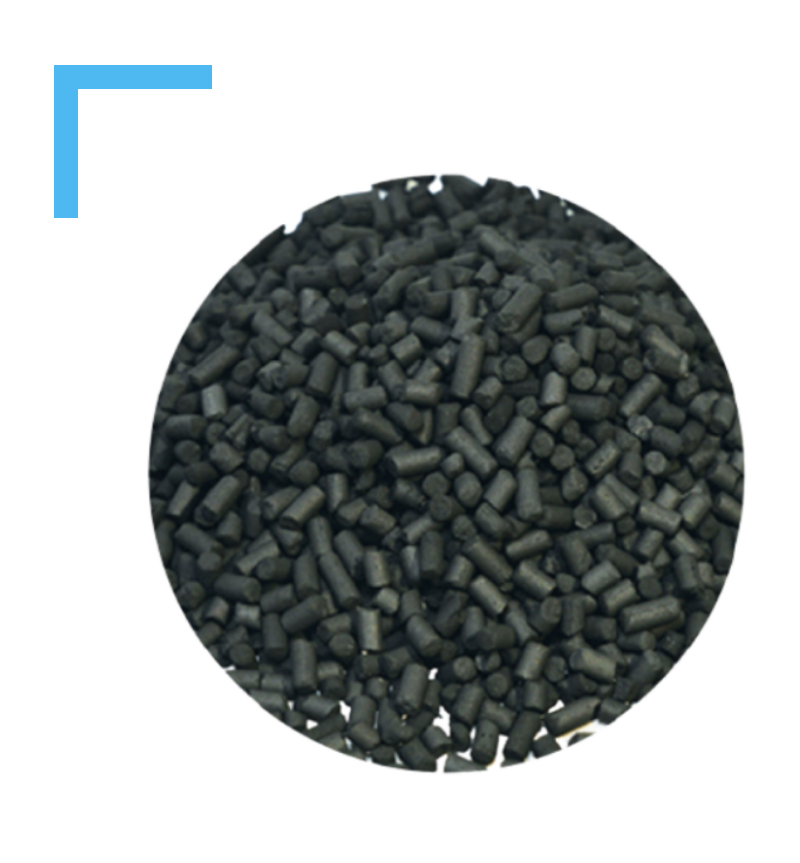

- Customized Media Selection for every requirement Activated Carbon, Ion Exchange Resin and Impregnated Carbon

- Very Low Dust Emission & Very Low Pressure Drop

- Available with various Frame Material and Tray thickness options

AP Trays

- Metal Trays c/w granular media

- 4×8 Mesh or smaller Mesh sizes

- Daftar Item

- Recommended for Low PPM to PPB levels of contaminants

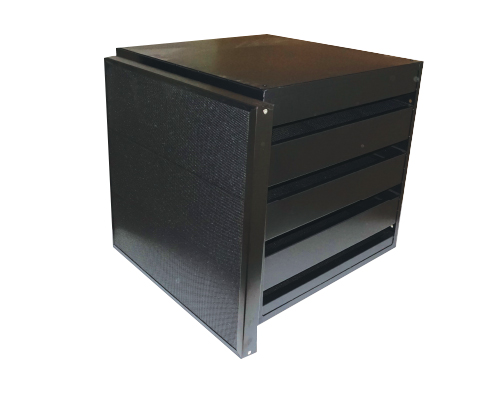

Cassette Modules : 18CS & 12CS

- Available in Plastic construction

- Contemporary, Low Resistance Design

- Optimized Design for Energy Efficient Performance.

- Available in 18” & 12” standard depths

- Suitable to work up to 500FPM (2.54m/s)

- Recommended for Low PPM to PPB levels of contaminants.

TerraComb

- Latest Technology in Chemical Filter Media

- Very Low Pressure Drop; High Energy Saving Potential

- Available in various specification and sizes

- Can remove wide spectrum of Impurities

- ULTRA LOW DUST Carry Over

- Totally Safe & Non-Toxic Fresh (New) Media

- Suitable for all types of installations, such as Deep Filtration Beds, Cassette & Canister Module equipment systems

- Easy to Install & Replace

STEP 3: MONITORING

Reactivity Measurement Kit

- Measure Air Reactivity as per ANSI/ISA-71.04.2013

- Qualifies & Quantifies the presence of Reactive Gases in the controlled Environment

- Handy tool & Very Reliable method to provide Air Quality Assessment Reports

- Can measure performance of the Chemical Filters installed

- Utilizes constant-current coulometricmethod accordance to ASTM B 825-02 to determine the corrosion rate of the exposed environment

Environmental Condition Monitor (ECM)

- Corrosion rate of Copper and Silver Sensors as per ANSI/ISA-71.04.2013

- Monitors corrosion rate, relative humidity, temperature and differential pressure

- High sensitivity corrosion rate measurement

- Provides both Digital and Analog outputs

- Optional storage in on-board datalogger that is accessible with PC software

Lab Services

- Monitors media usage for a gas phase filtration system.

- Analysis is capable to predict chemical media’s remaining life

- Information obtained can reflect;

- Existing system’s characteristics and effectiveness

- Replacement cycle necessary for maximum performance.